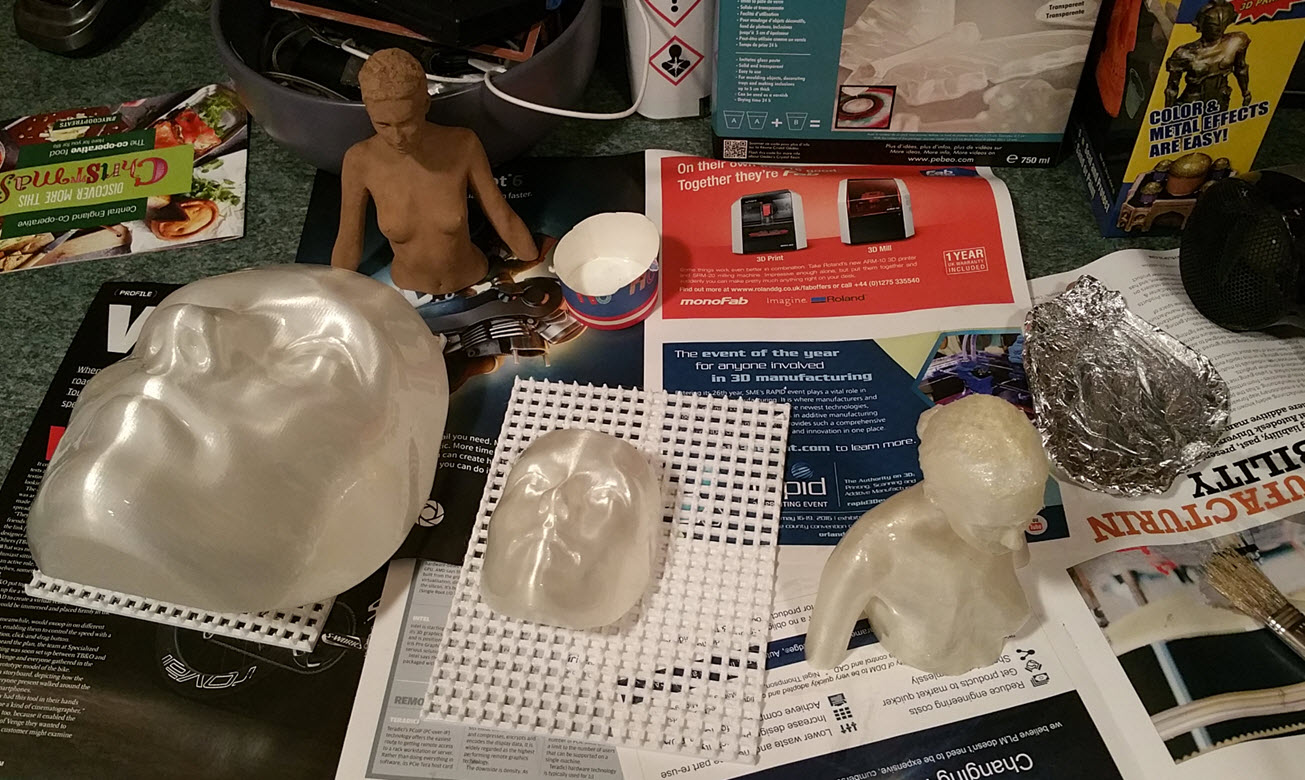

XTC-3D Finishing Resin and Natural PLA

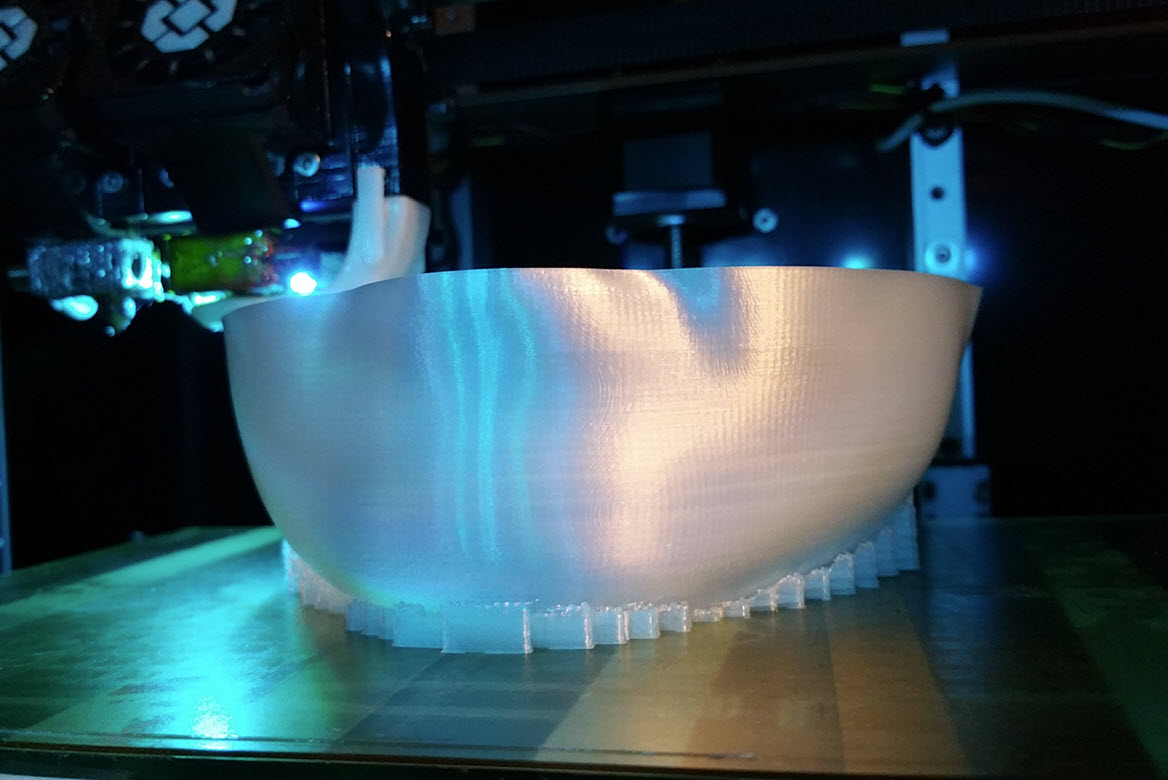

I’ve been wanting to try Smooth-On’s XTC-3D finishing resin on a PLA part for a while now. When a friend asked me to print Sonia Verdu’s wonderful Mascar-veneciana mask, I saw this as a good opportunity to kill two birds with one stone.

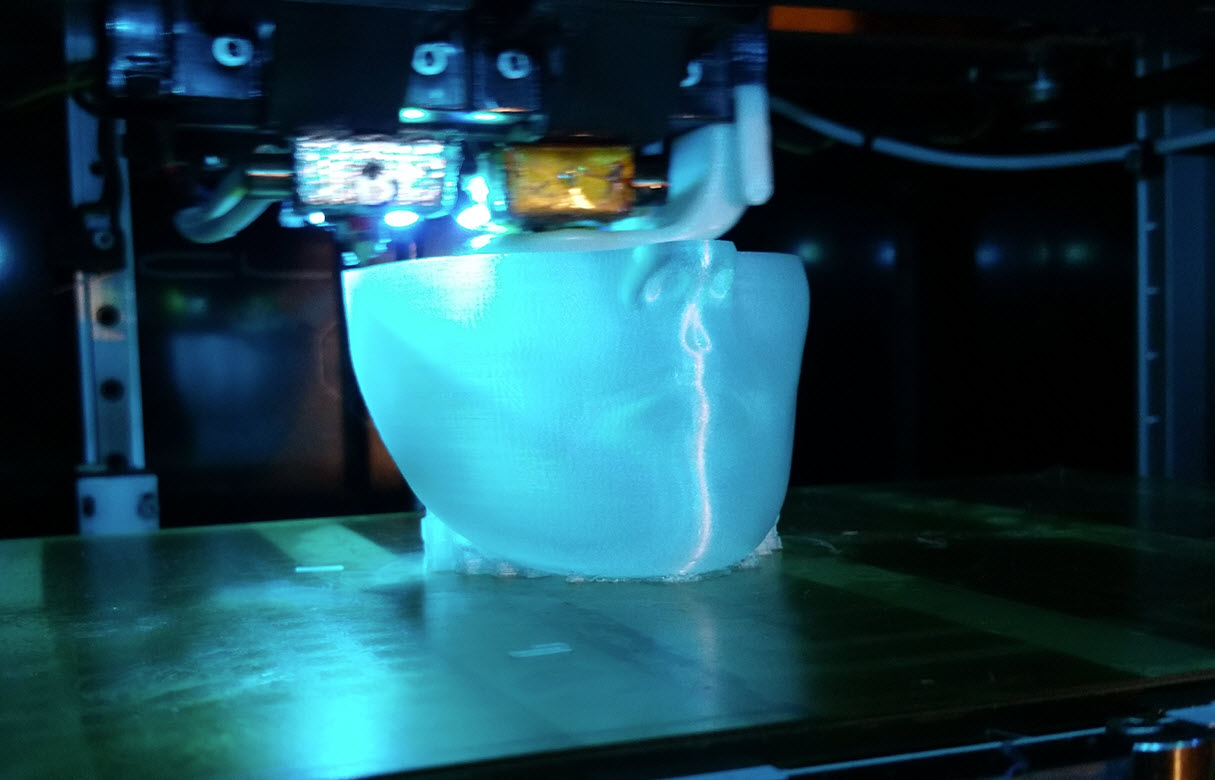

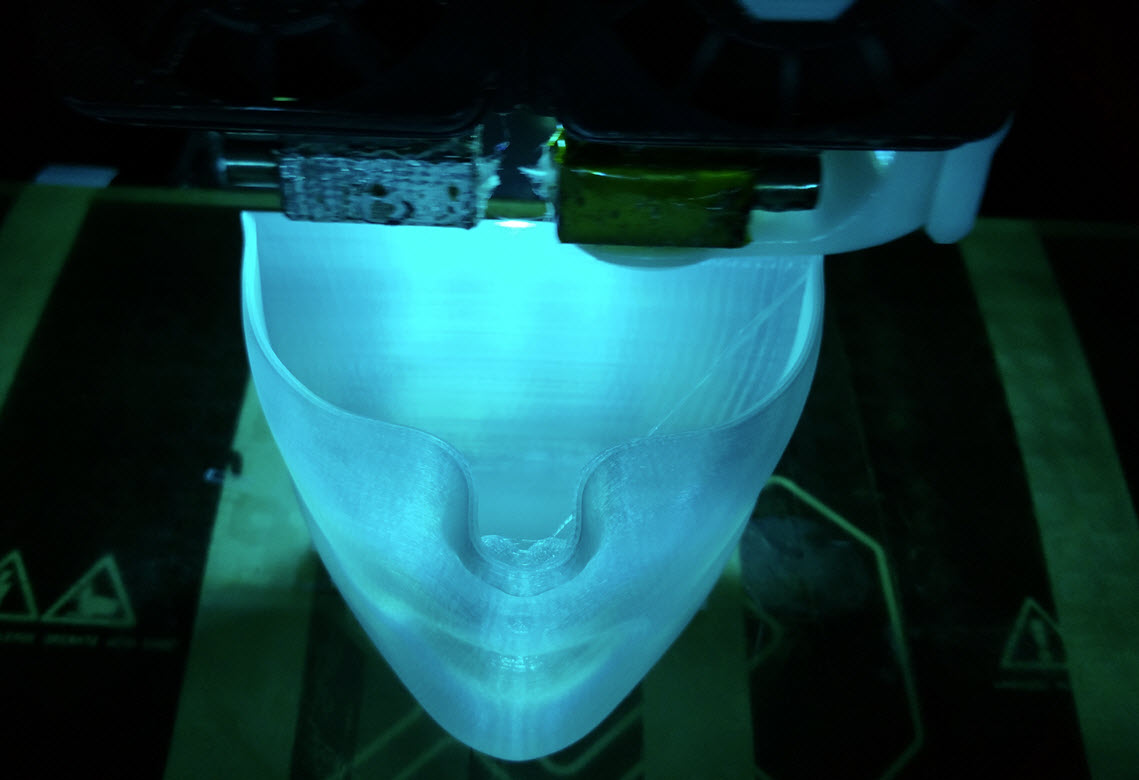

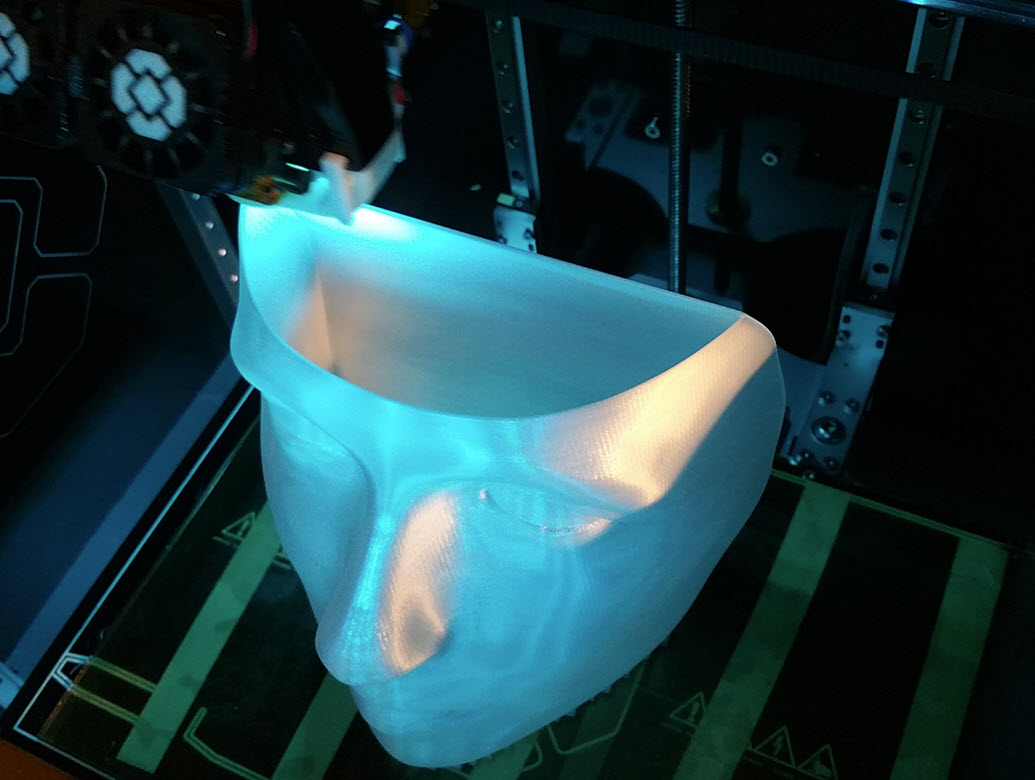

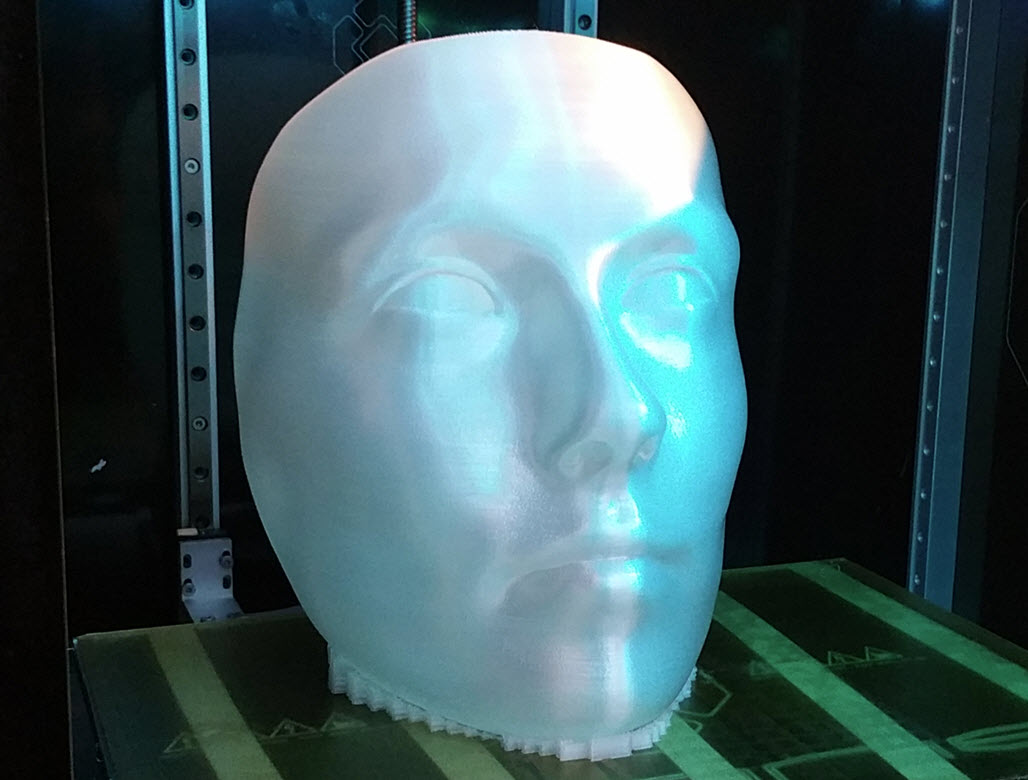

The Mascar-veneciana mask was printed in some old transparent blue PLA and I wasn’t expecting such good results.

After a couple of coats of XTC-3D, the finished surface took on a real mother of pearl feel. Completely unintentional and one of those happy accidents you sometimes stumble upon.

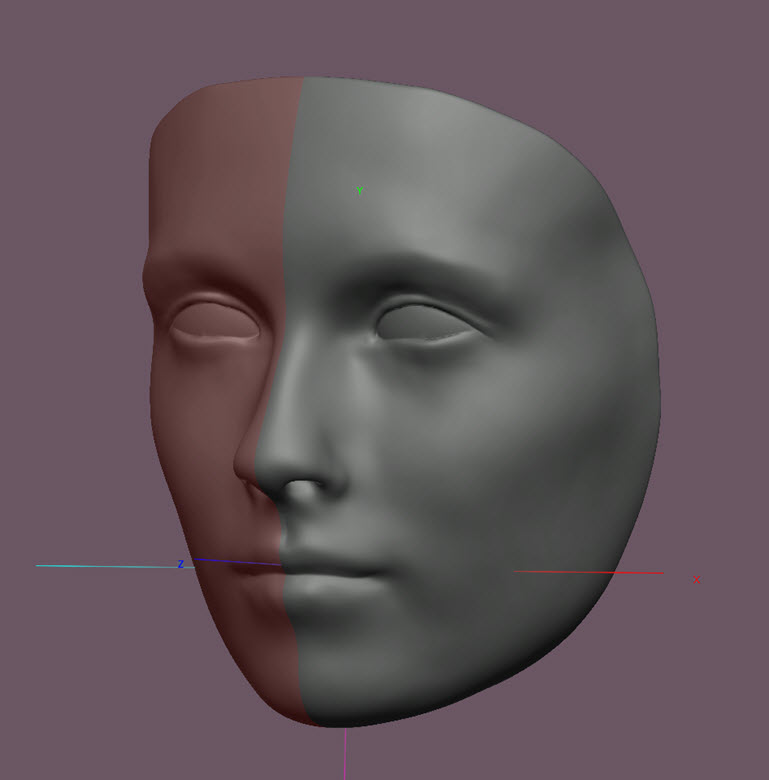

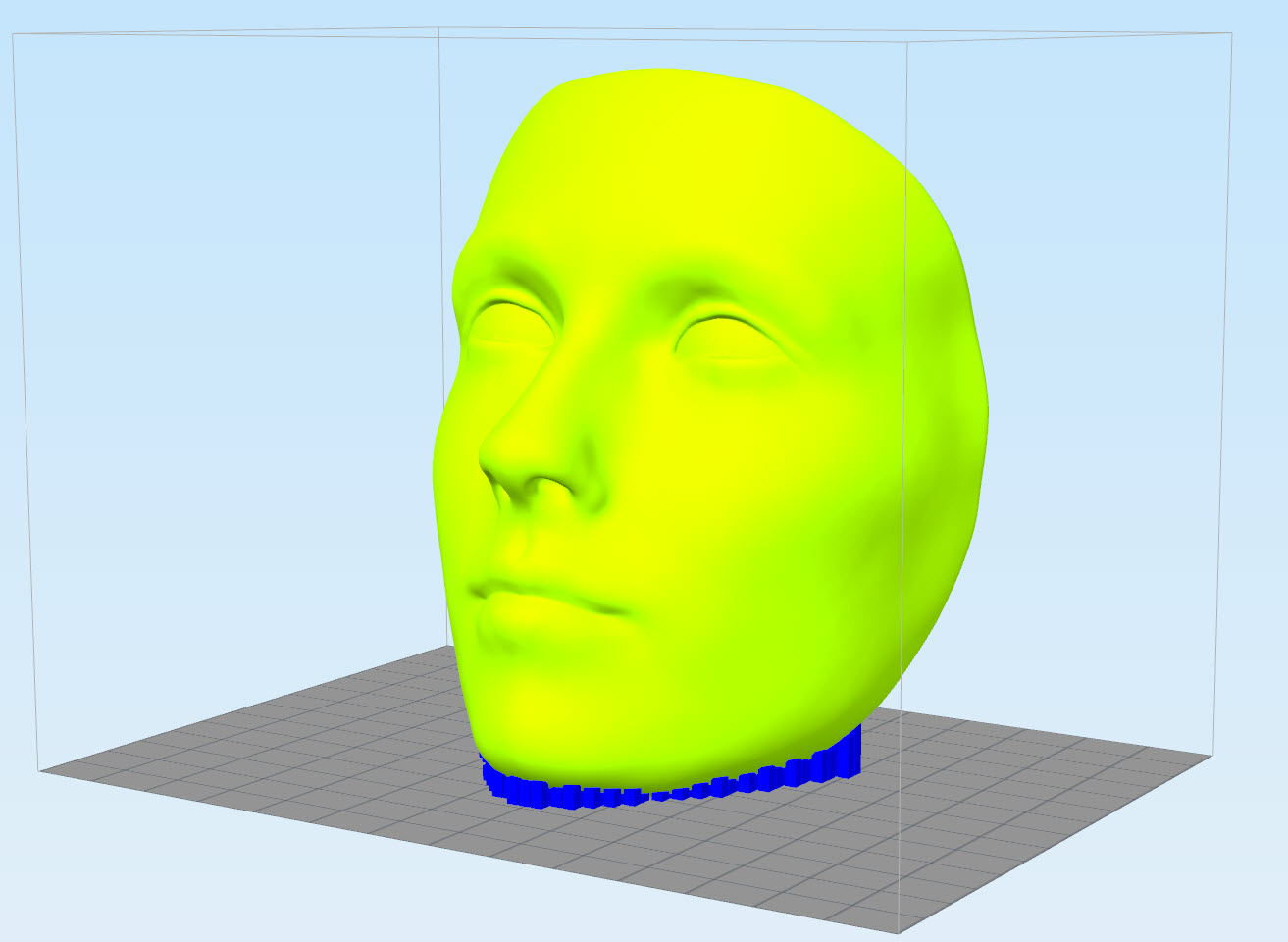

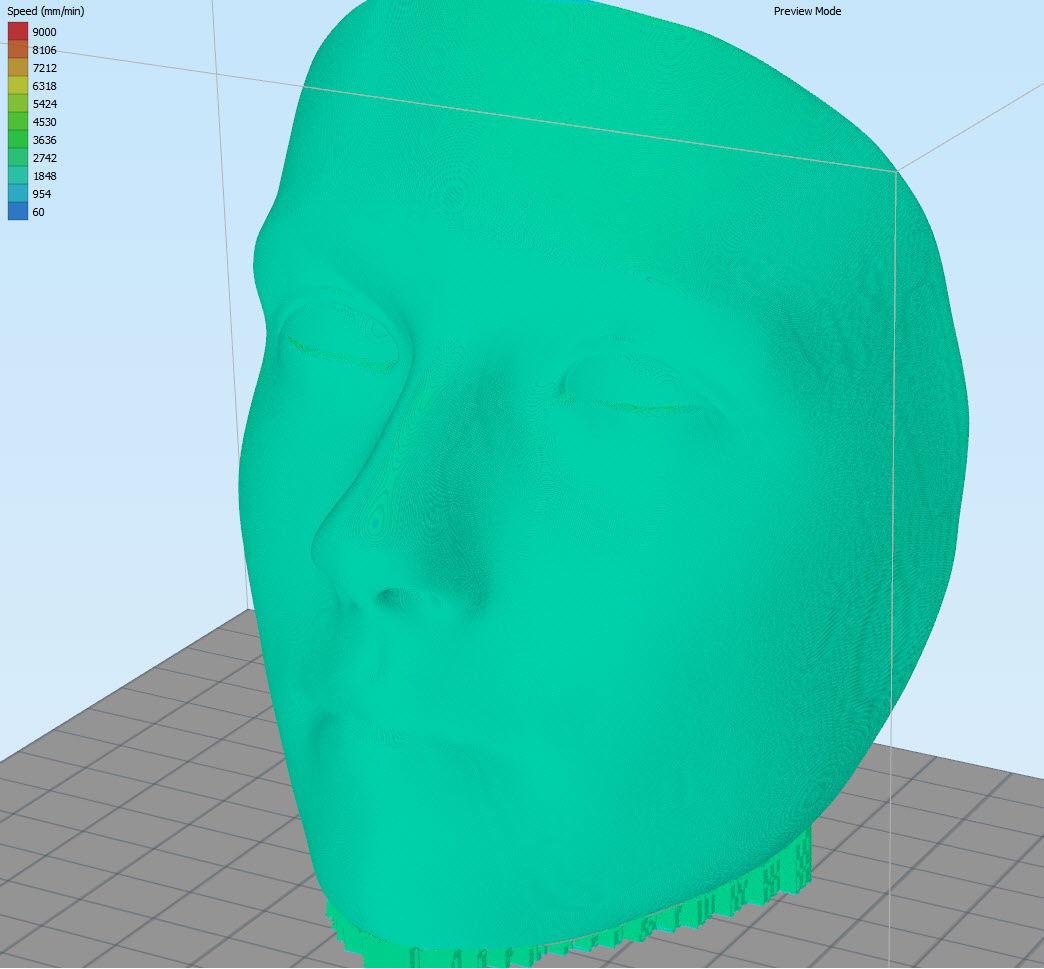

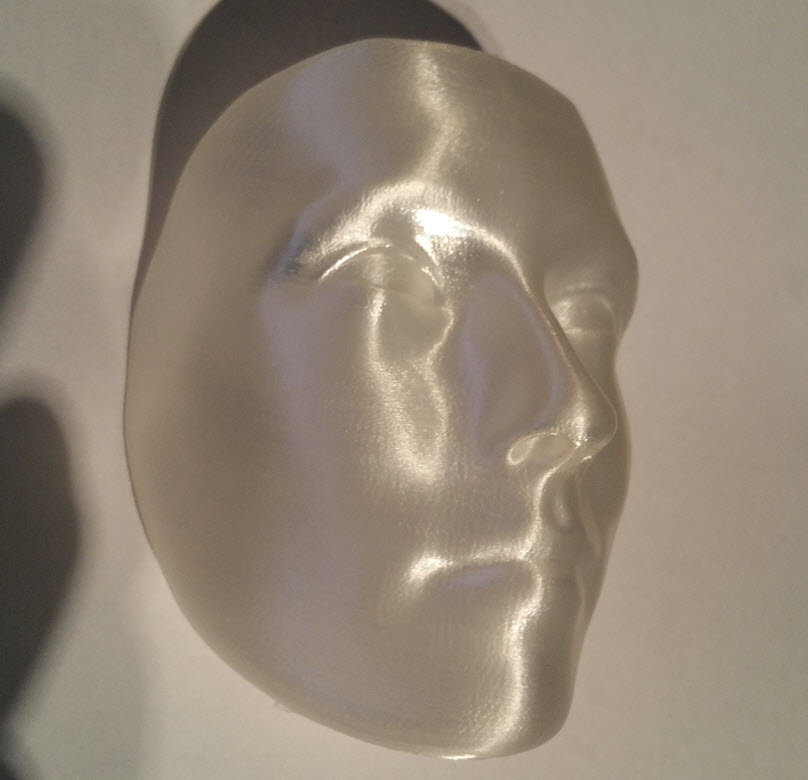

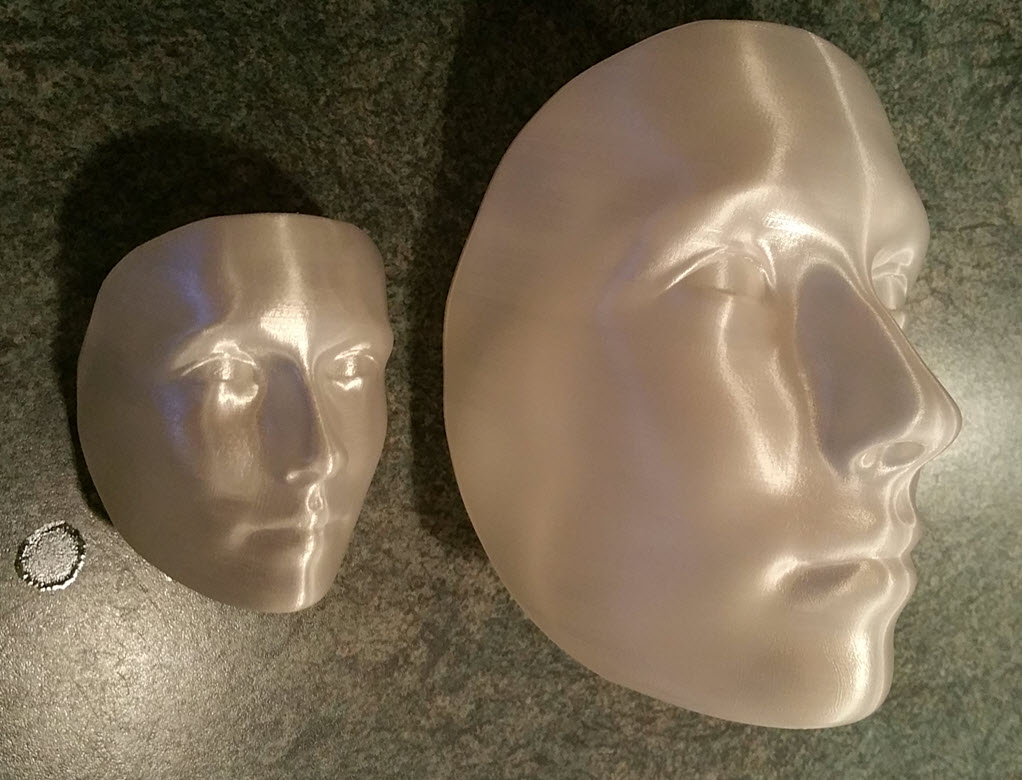

After seeing how well the final mask turned out I tried the same finishing technique on a life size scanned face that I had been practicing with in 3DCoat.

The 3D Scan I had been playing with in 3DCoat was printed in natural PLA. It looked really beautiful after printing, even without the post processing.

Things I’ve learnt with this project

- Natural PLA doesn’t look great on the spool, but after printing… WOW.

- Natural PLA identifies print issue like ringing really well.

- XTC-3D won’t turn a “sow’s ear into a silk purse”.

- The better your initial print, the better your end result is going to be.

- Preparation is everything.

- Don’t rush – get your surfaces as smooth as possible before applying XTC-3D.

- Wire wool works great for smoothing out print striations in PLA.

- Two lighter coats of XTC-3D are better than one think one.

- Apply any additional coats just as the previous coat starts to go off.

- XTC-3D sands really well when fully cured.

- XTC-3D really strengthened the thin wall prints.