SAKAI GW750 Custom Cab & HVAC

The Sakai custom cab is my largest solo project to date and included a 2 week visit to TRACS Australia. The interactive proposals where key in securing the initial order as it allowed the customer and end users to visualize the cab the design principals.

The final 3D assembly consists of 3126 components, 530 of those being unique. The completed cabs are now delivered on a stillage, fully assembled and require minimal work for fitting to the Sakai rollers.

Some of the design challenges included –

- Ensuring maximum visibility for the operators

- The cab had to fit around and not interfere with the factory ROP (Roll Over Protection)

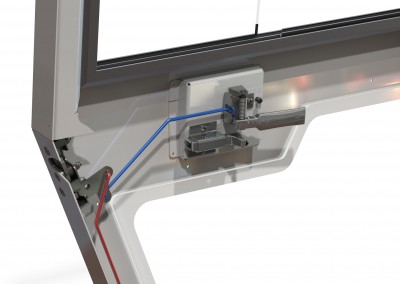

- Observe TRACS no drill policy requirement. Cab modules should only be attached to the chassis using existing bolt holes and mounting points.

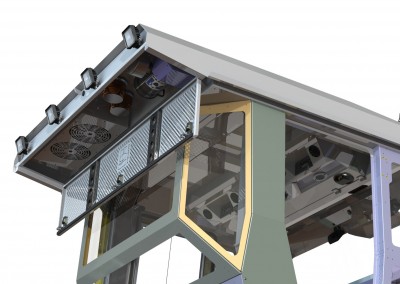

- A sealed cabin to incorporate TRACS cab pressurization and air filtration systems

- Packaging a bespoke HVAC System

- Acoustic noise reduction wherever possible

- Modular, bolted construction, with all panels 100% powder coated

- Self-Jigging sheet metal modules to aid fabrication

- Assembly videos to assist fabrication and minimize manufacturing errors

- A high emphasis serviceability of AC and filtration components

- Four bespoke door hinges and assembly jig

- Assembly, lifting and transportation jigs and stillages

Design Discipline

- Concept Development 10%

- Product Visualization 5%

- Design for Manufacture 85%

Software Utilization

- SolidWorks 80%

- PhotoView 360 8%

- 3D Via Composer 2%

- Adobe Design Premium 10%